Most Popular Products

|

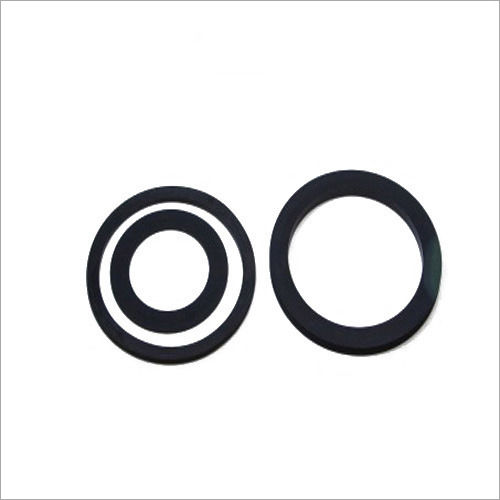

Rubber Seals

Product Details:

- Color Black

- Product Type Rubber Seals

- Usage Industrial

- Material Rubber

- Shape Round

- Click to view more

X

Rubber Seals Product Specifications

- Black

- Rubber Seals

- Round

- Rubber

- Industrial

Product Description

Rubber seals are widely used in various industries for sealing applications, primarily to prevent leakage of fluids or gases between two surfaces. These seals are made from rubber or elastomeric materials, which offer flexibility and resilience to deformation, enabling them to conform to irregular surfaces and maintain a tight seal under different conditions.

Here are some key points about rubber seals:

Material: Rubber seals are typically made from synthetic rubber compounds such as silicone, EPDM (Ethylene Propylene Diene Monomer), Nitrile (NBR), or natural rubber. The choice of material depends on factors such as the application requirements, chemical compatibility, temperature range, and environmental conditions.

Types: Rubber seals come in various types depending on their shape, size, and application. Some common types include O-rings, gaskets, lip seals, diaphragms, and custom-molded seals.

Applications: Rubber seals find applications in a wide range of industries including automotive, aerospace, marine, manufacturing, plumbing, HVAC (Heating, Ventilation, and Air Conditioning), and hydraulic systems. They are used in engines, pumps, valves, pipes, doors, windows, and many other components and systems where sealing is critical.

Functions: Rubber seals serve multiple functions such as preventing leakage of fluids or gases, minimizing contamination, providing cushioning or vibration isolation, and resisting wear and tear due to friction and environmental factors.

Installation: Proper installation of rubber seals is essential to ensure effective sealing and optimal performance. This may involve cleaning the mating surfaces, applying lubricants or sealants as needed, and ensuring proper compression or alignment of the seal.

Maintenance: Regular inspection and maintenance of rubber seals are necessary to detect any signs of wear, damage, or deterioration. Replacing worn or damaged seals promptly helps prevent leaks and prolongs the lifespan of equipment and machinery.

Environmental Factors: Rubber seals may be exposed to various environmental factors such as temperature extremes, chemicals, UV radiation, ozone, and mechanical stresses. Choosing the right material and design for the specific application is crucial to ensure durability and reliability.

Customization: Rubber seals can be customized to meet specific requirements such as size, shape, hardness, and performance characteristics. Custom molding and engineering services are available to design seals tailored to the unique needs of different applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Hydraulic Seals' category

|

PASUPATI SALES & SERVICES PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |